New learnings, new project

A tram, a street sweeper, and a bin walk into a bar...

After a fairly successful experience with the Tramsformer project, I decided that far from being burnt out to the point of never wanting to see another 3D printer or toy robot ever again, I was finding myself inspired by the skills, achievement, and learnings I’d gained from the whole journey. Ideas that previously would never had occurred to me or felt beyond my ability were now not only possible but viable with the major limiter now being time and mental energy outside of work hours. That said while I was itching to start a new transforming robot project, I wasn’t quite ready to jump into another huge engineering undertaking just yet so there were a few new constraints I wanted for the next round:

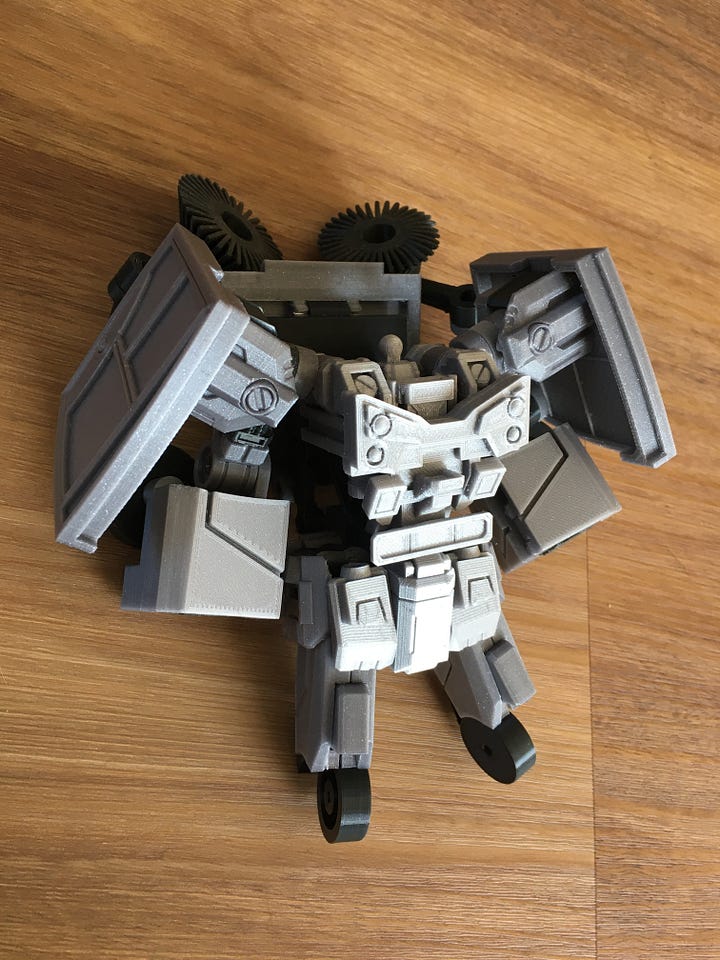

Easier assembly - By far the biggest challenge and bottleneck with the Tramsformer was assembling for production. After many tired evenings of fiddly handling of tiny screws, pliers, glue, and paint I wanted to make sure that any future design must be not only easy to produce parts for but also require minimal cognitive and physical effort to assemble as possible. Each Tramsformer unit took upwards of 10 hours of clean up and assembly before they were ready for packaging. I needed to do better than that.

Easier parts production - I wanted to be able to prototype and iterate faster and experiment with new techniques and ideas sooner without the chore of cleaning up complicated prints or tinkering with print settings because of design complexities. This is something much easier to do while I’m still at the design stage rather than retrofitting a 95% complete model.

Simpler transformation - The Tramsformer isn’t easy to transform, even with the instructions. I’d like the transforming experience for the next one to be more joyful than frustrating.

As with the tram, I wanted the vehicle/alt mode of this new bot to be something mundane, ordinary and relatable to everyday folks. After a false start with attempting to transform a street sweeper vehicle, I decided to add to the list:

Smaller scale - In an attempt to address some of the assembly and printing challenges, I’d opted to design the street sweeper as a larger model. Unfortunately in doing so this lead to a tendency to over-engineer much of the transformation and moving parts simply because there was space to do so. The part groups were big and complicated and the project lost steam. I needed to bite off something smaller that I could handle.

It was waaaaay simpler in my head.

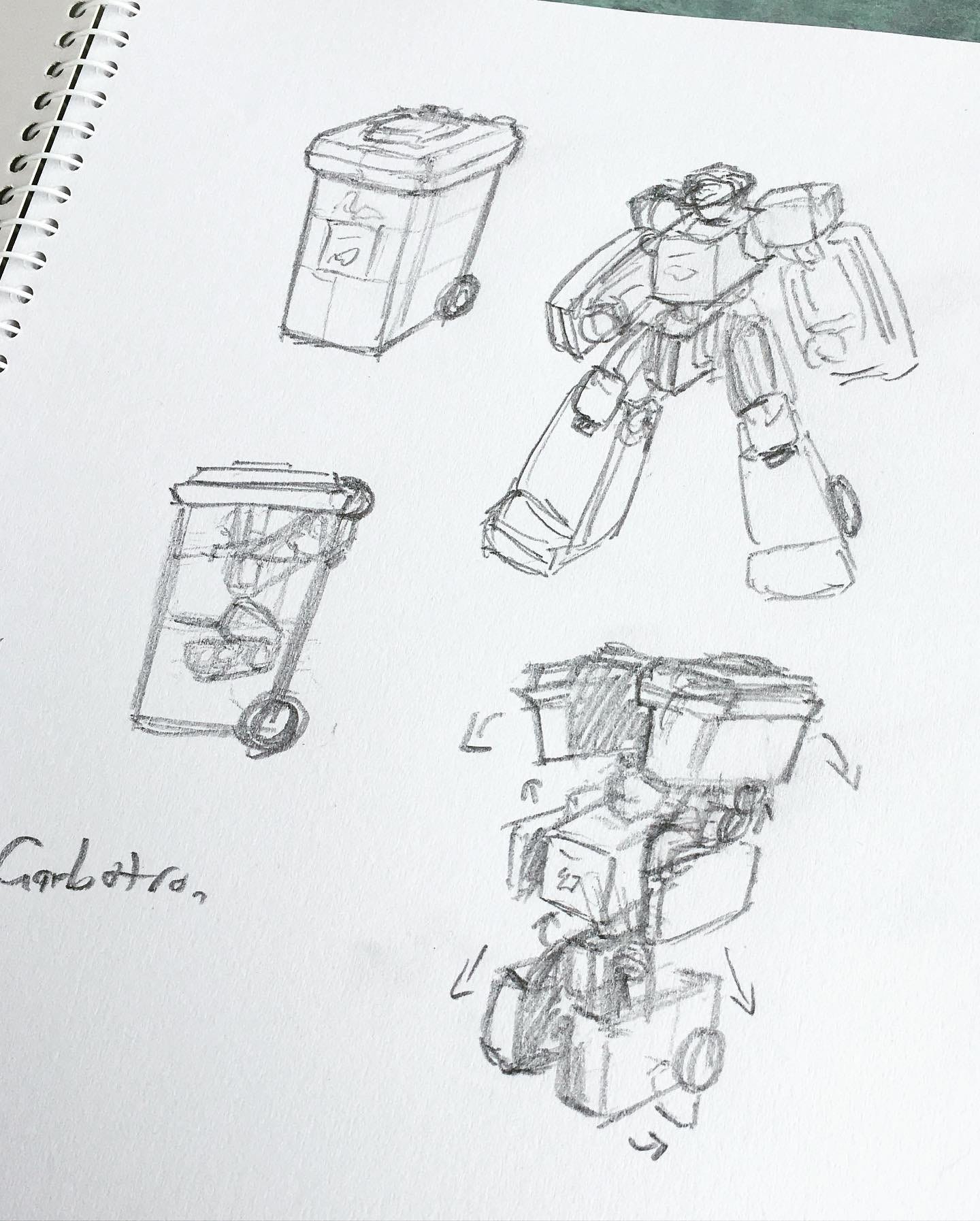

While the Street Sweeper sadly got shelved (for now), it wasn’t without some extremely valuable learnings, the key one being figuring out how to implement 1.5mm steel pin hinges. This would open the doors to much smaller scale designs that could robustly accomodate moving parts in spaces that screws couldn’t fit. I decided to try this on an idea I’d scribbled in a notebook after a few glasses of wine while on holiday in Portland last year: a wheelie bin.

I’ve got a good feeling about this :D