The street sweeper

A retrospective

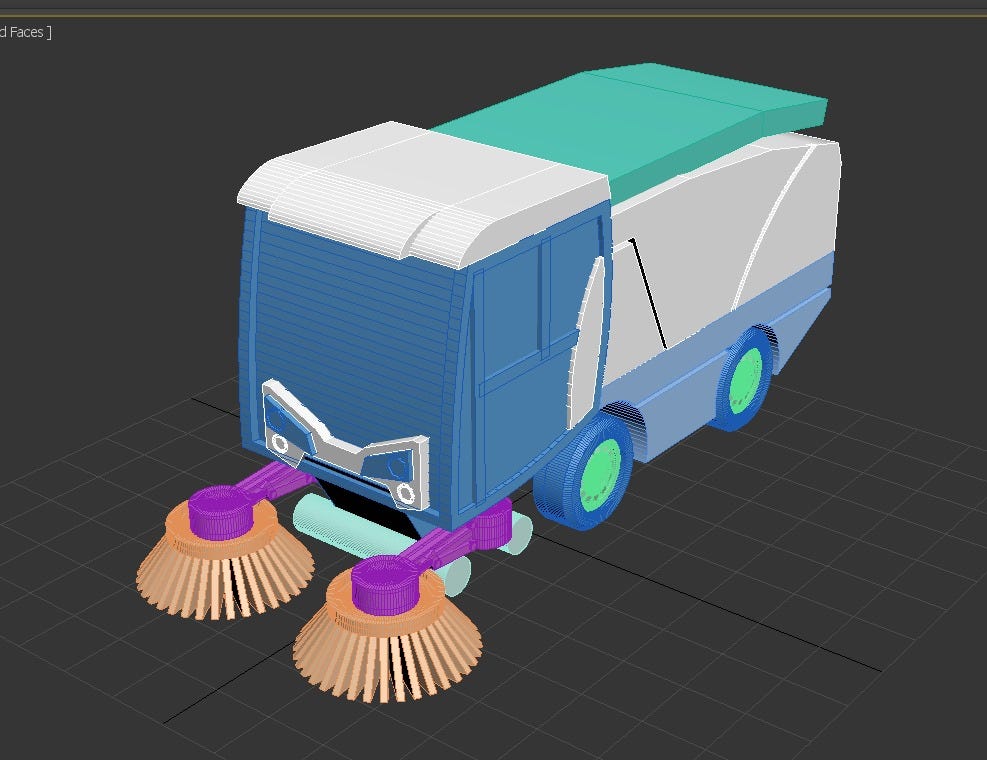

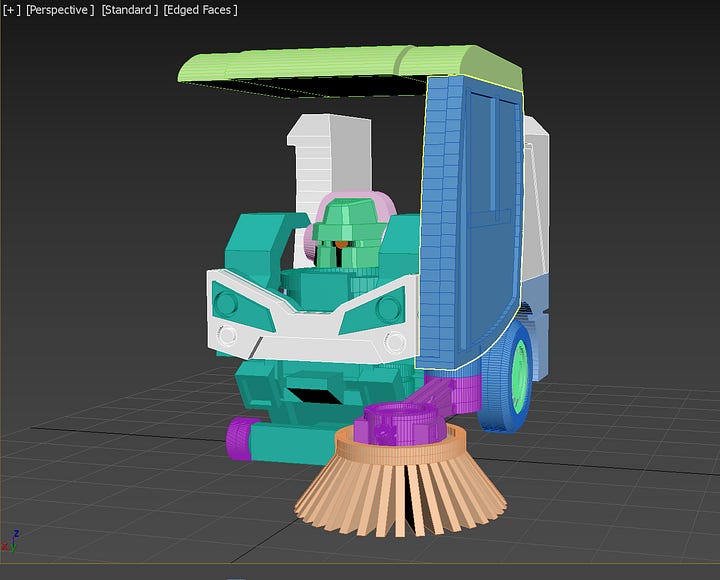

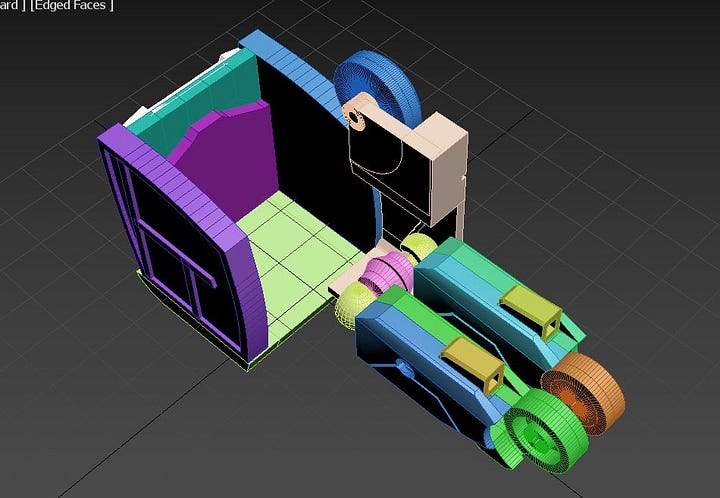

Like most projects the journey of the Binformer has not been a linear one. In fact, it almost didn’t even happen (at least not yet) as the next bot I was making was actually going to transform into a CN201 Compact Sweeper vehicle.

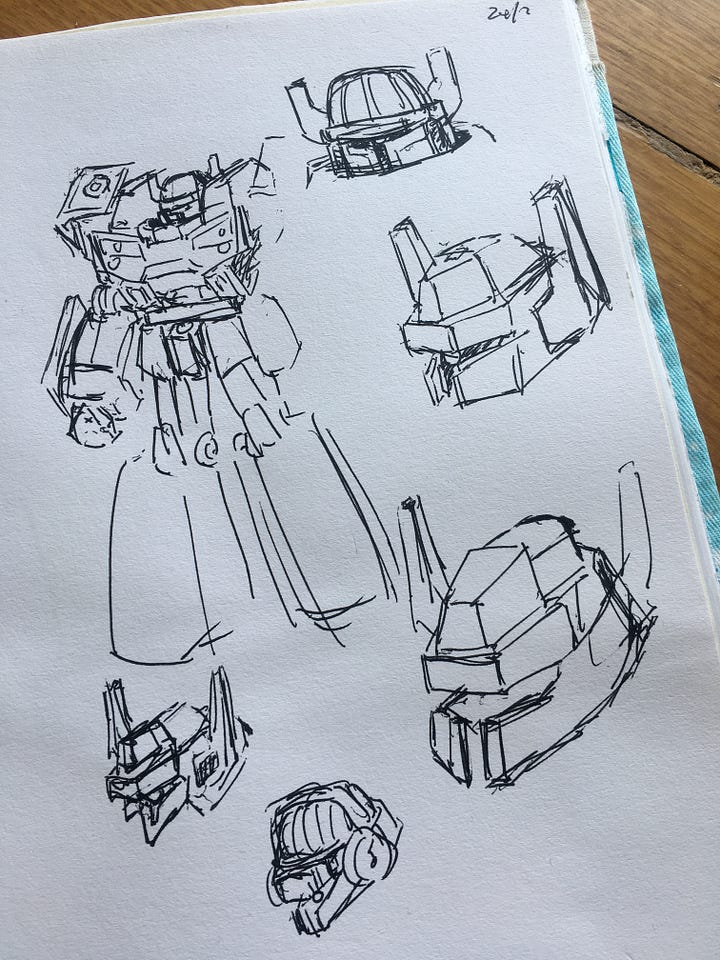

As with the tram before it I wanted to continue turning items of the boring, everyday Australian experience into something fun and exciting that the local layperson could relate to and connect with regardless if they were fans of a certain transforming robot toy franchise or not. However I also wanted a simpler project. I wanted to work with something smaller (and as I reasoned at the time, easier to transform) than a tram as well as explore more of our icons beyond public transport. Even though I was working from home by that time, my imagination was still very much inspired from my days working 9-5 in a city office. A quintessential part of my daily city commuting experience was the walk from Flinders St station to the office where no matter what street I was on, long before I would see them I would hear that unmistakable whirring of the morning street sweepers slowly making their way around the footpaths. From a shape and proportions perspective, they are short and boxy which makes them much easier to cut up and arrange into robot than a tram or carriage without the need to find clever ways to use up excess length. So when it came to deciding what I would transform next, a street sweeper seemed an easy choice.

So what went wrong?

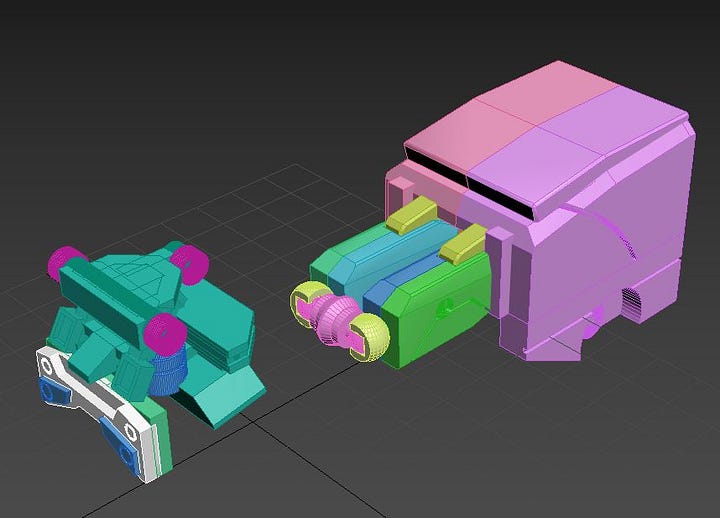

Well nothing at the start. In fact the initially rough cut up of the vehicle suggested that things would fit quite well together within a sensible number of parts. It wasn’t until I’d decided to upscale the model by 50% (at the time for improved parts strength) did complexity start to creep in. While I could now implement more intricate joints and smaller moving parts, I was also no longer sticking to the enforced design simplicity that came with working in limited space (a constraint I had deliberately prescribed myself at the start but conveniently forgot). So what followed was basically:

I need to move this part from here to there.

But wait, I have room for more detail/articulation/gimmicks, I can just divide this part up for better assembly…

Now there are more parts.

Repeat.

It took a few rounds of that before I realised I’d fallen back into the trap of being driven by perfectionism, and wanting all the features, all the details, all at once. My cup wasn’t being refilled by the progress and wins anymore and I was spending more time being dissatisfied than appreciating my work. This project just wasn’t fun anymore.

That’s the circuit breaker.

One of the big lessons I picked up from my creative pursuits over the years is that when a hobby project is forced to completion with nothing behind it but joyless grind, the feeling of crossing the finish line under those circumstances feels like a cheap, short-changed version of the amazing uplifting high you expect after a major accomplishment. Rarely will I be looking at my best work as much of the patience required to bring that out will have been jettisoned in that mad dash to the end. It feels like being cheated out of something worked so hard for. So I made the decision to shelve the project (despite being 75% of the way through) for now and maybe come back to it when I’m ready again.

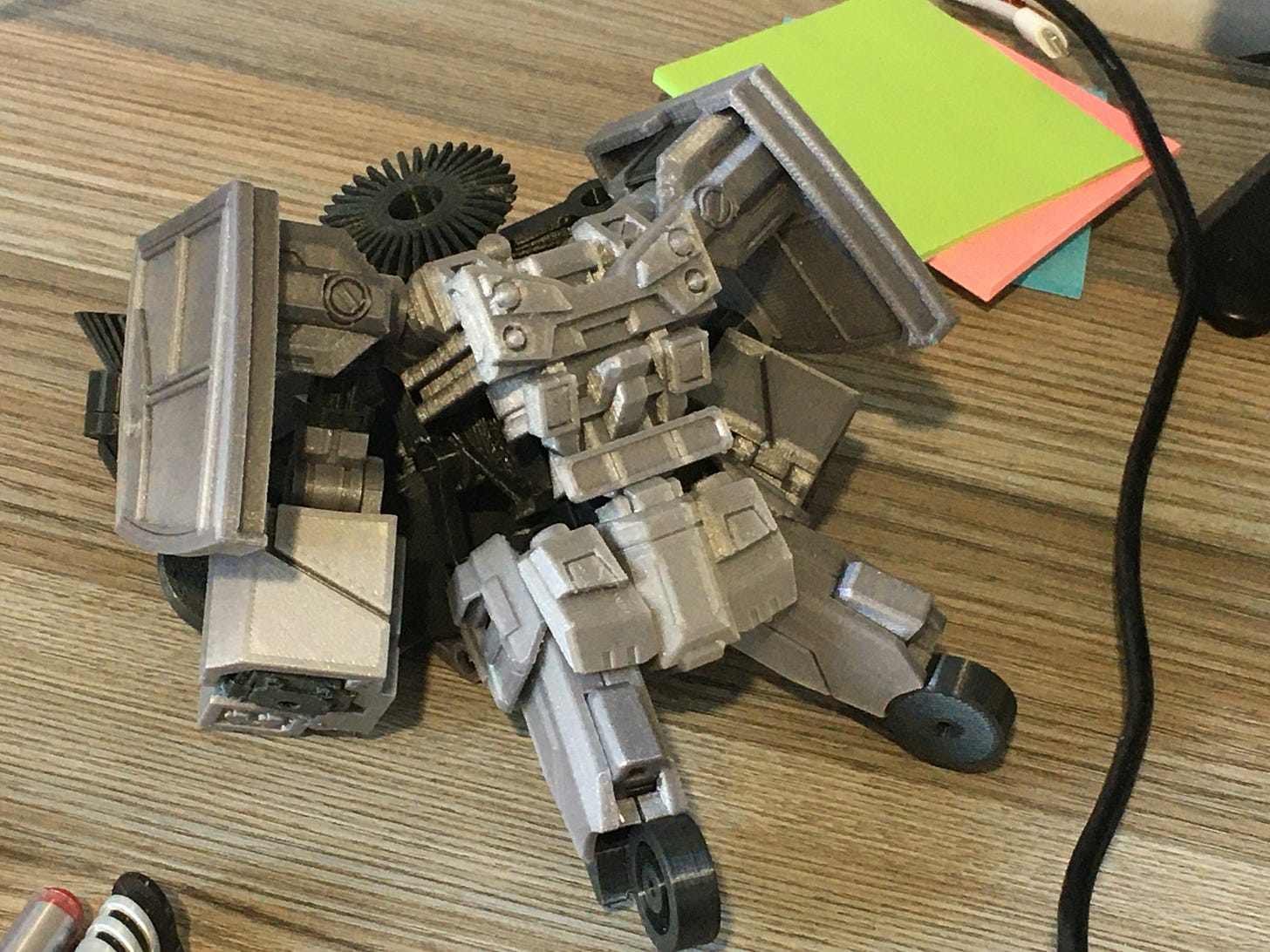

So sitting here with an incomplete robot that doesn’t even have a head, was it worth it? Absolutely. Even though the project didn’t get to finish, it served well as a test bed for new ideas with many valuable take aways:

Steel dowel pins - The tram used screws to facilitate hinge joints which while did the job, were a bit clunky and not great in limited space scenarios. Figuring out 1.5mm steel pins has enabled all the robustness a screw solution provided with the added benefit of fitting in much tighter spaces. This enables a lot more options on implementing any sort of folding panel or hinge solution.

Design for the whole production process, not just the finished result - The major bottlenecks in the Tramsformer production journey were by far the parts prep and assembly steps (10+ hours per unit). This time round, I was very conscious of making sure that the parts and movements were designed in a way that were not only easy to print, but simple enough to put together without needing a huge reserve of cognitive effort. Assembly has been much less stressful this time round.

Fun factor - For hobby projects like this, fun is better than done, and done is better than perfect. When it stops being fun, it won’t get done and if it doesn’t get done, it probably won’t get iterated on to get good enough to perfect. It’s also fine (and in fact probably healthy) to take breaks, especially when the well of joy starts to dry up. Come back to it later when you’ve refreshed.

So completed or not, the Street Sweeper has served its creative purpose well and the fruits of the project will be carried over to the next one. In the meantime, it’ll sit on my desk as a reminder of something to look forward to; even in its incomplete form, I’m still damn proud of it.